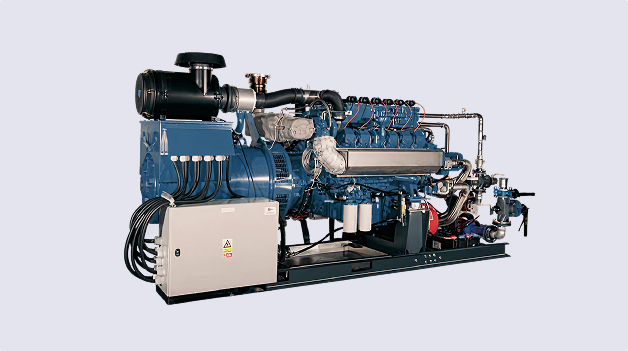

MTU 8V4000

-

ENGINE TYPE

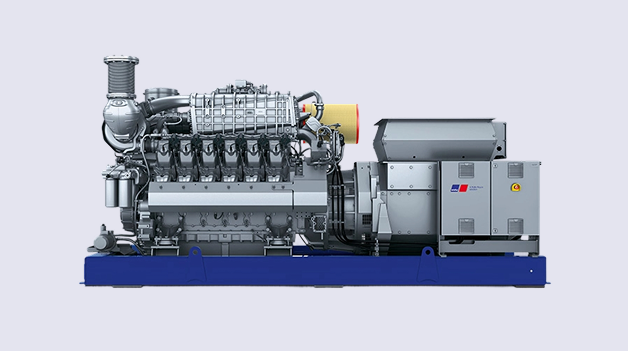

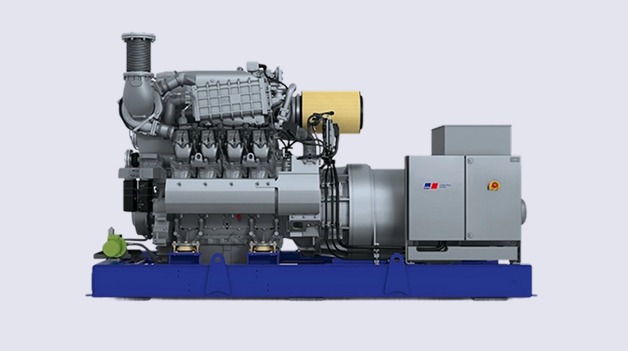

MTU 20V4000L64FNER

-

version

Open Frame

-

ELECTRICAL POWER (kW)

1,013 kW

-

Thermal Efficiency

44%

-

Thermal Efficiency

-

-

Fuel consumption at 100% load

250 Nm³/h natural gas